A Guide to Vertical Form Fill Seal (Vertical Bagging)

Learn about vertical form fill seal - the method of packing where the bag is created during the filling process.

Read More

Horizontal form fill seal, or HFFS for short, is a popular packing process that’s chosen by all kinds of businesses. In this blog we’re explaining the difference between the HFFS and VFFS (vertical form fill seal) systems.

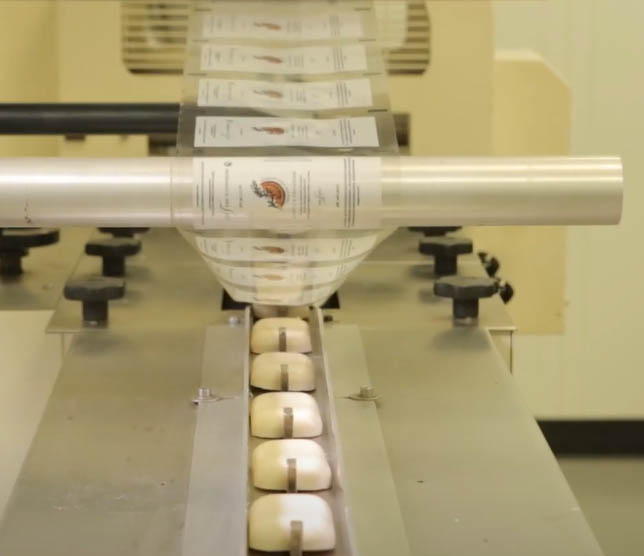

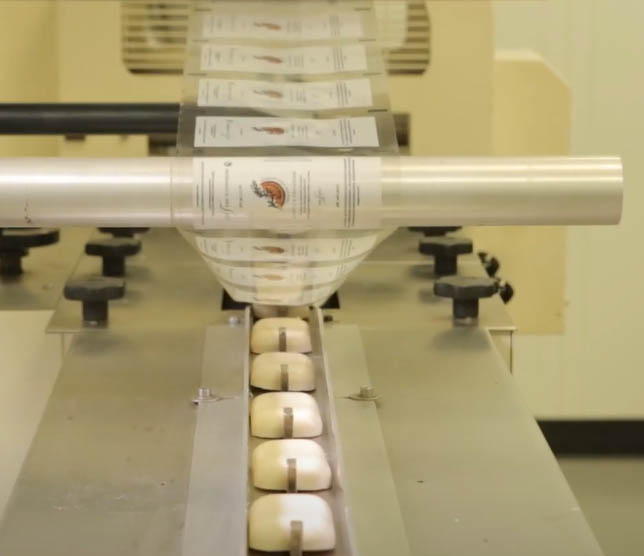

As the name suggests, this method of packing operates horizontally. As products move along a conveyor belt, they are wrapped in plastic film which is then sealed at both ends. HFFS is very popular because up to 70 bags can be packed per minute as part of a highly efficient system.

HFFS is also known as flow wrapping and it’s perfect for solid items of the same shape and size, which could be anything from biscuits, snack bars and cakes to leaflets, tissues, toys, accessories and bundled products. If you have a high-volume packing project that requires between 2,500 and 50,000 bags or more, make sure to ask us about HFFS.

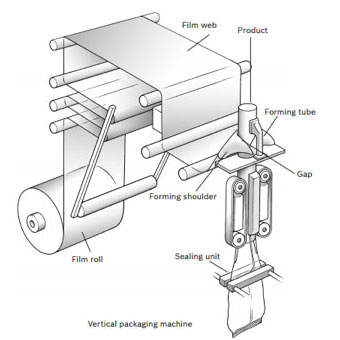

Vertical form fill seal is similar in a way, in that it is a continuous system for forming, filling and sealing packaging. However, the process is carried out vertically, with the sealing of one unit causing the formation of the next. As a result, time and materials are optimised, as the machinery vertically creates filled and sealed units with minimal waste.

HFFS comes with other benefits, such as keeping each bag’s contents protected through robust plastic film that restricts movement and provides an airtight finish. Horizontal filling can be combined with gas flushing to ensure that all oxygen is removed from the bag before being sealed, which is well suited to food items that need to remain fresh. On top of this, here are a few additional advantages:

We’re here to help you understand how packing processes work, so here are a few other differences between HFFS and VFFS:

If you’re interested in our flow wrapping or vertical form fill sealing services, we’d be delighted to answer your questions and help you to customise our offering to your exact requirements. To find out more, get in touch on 0115 852 9000 or fill in our contact form.