Introduction to Vertical Form Fill Seal Machines

The vertical form fill seal machine is a popular method for filling packaging with confectionery, powders, rubs, seeds and more.

Read More

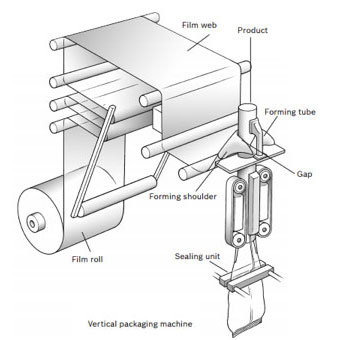

Vertical form fill seal (VFFS) is a method of packing where the bag is created during the filling process. In simple terms, it involves feeding the product into a bag vertically as opposed to horizontally. This is what it looks like in action:

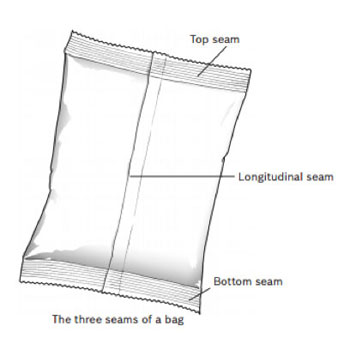

VFFS bags have three seams as demonstrated in the illustration above.

VFFS is a flexible, quick way of getting a loose, dry product into air-tight, portion-controlled packs. These are known as free flowing products. Depending on the material of bag and laminate used VFFS can preserve your food or product. VFFS can be used to create smaller sachets that sit inside larger packaging, for example a small bag of salt inside a packet of crisps. This type of packing can also be combined with something called gas flushing which helps to preserve your raw material for longer.

Also known as Modified Atmosphere Packaging (MAP) gas flushing involves repeatedly injecting and removing an inert gas into the package in order to eliminate oxygen. The inert gas (something like carbon dioxide or nitrogen) is denser than oxygen so it pushes the oxygen out of the packaging.

The benefits of gas flushing are:

In some situations, depending on the type of product, oxygen may be retained in the packaging. For example;

Anything loose, granular and relatively dry. Things like powders, rubs, spices, sweets, seeds, sand beads, blends or ingredients and similar products. VFFS can be used for food and non-food alike. Raw material is normally received in 15kg – 20kg sacks, buckets, drums or similar. If you have a large delivery just get in touch, we can handle any size of delivery. At present, WePack doesn’t pack liquids using VFFS.

Any square or rectangular bag can be made on a VFFS machine.

Width available:

Length available:

Colour & print available:

Vertical form fill seal creates a pillow bag shape that looks like this:

A target weight can be set for each bag meaning you can achieve consistency across all your products and achieve a “minimum fill” so that no bag is underweight.

Bags are sealed using heat and pressure to create a crimp seal. Seals can vary in terms of how flat or pronounced they are. Good vertical form seal is all about minimizing the length of the seal, so that unnecessary material isn’t used, and so that the final bags are easy to pack together in larger, outer packing for transportation.

There are lots of different materials that can be used to make the bag. Normally a polyethylene terephthalate (PET) or Polyethylene (PE) film is used, a common type of plastic. This a strong, robust material that has good sealing properties and will keep many products fresh for a reasonable length of time.

Laminates are used as extra layers to protect the raw material. For example, a foil laminate is often used in combination with PE or PET to protect flavour or prevent the smell from leaking out through the film. Generally, laminates are used:

Foils and variable gauges of PE, PET, Polyester laminates are commonly used to control these challenges.

Some raw materials can damage the laminate so it’s important to know the chemical make-up of the product and choose an appropriate laminate. Different laminates are tailored to the specific needs of the product inside – there are lots of varieties available.

Water-soluble film – a film that dissolves completely when put into water – is also available.

Your contract packing company should be able to advise you on the right laminates to use depending on your raw material.

The process happens quickly – approximately 30-40 bags can be produced per minute, working with a 65mm x 65mm bag and granular product.

To find out more about Vertical Form Fill Seal (Vertical bagging) please contact WePack on 0115 852 9000 or get in touch via the form below.