A Guide to Flow Wrapping (Horizontal Bagging)

Flow wrapping is used for packing solid items including biscuits, scratch cards and pharmaceuticals. If your business is looking to utilise flow wrapping for your products, this guide can help.

SEE OUR FLOW WRAPPING SERVICES

In this guide

This guide will explain what flow wrapping is, highlight the best-suited products and answer frequently asked questions.

- What is flow wrapping?

- What type of product is flow wrapping suitable for?

- What will the bag look like?

- What benefits does flow wrapping offer?

- What materials are used?

- How does flow wrapping work?

- What quantities can you work with?

- How long does the process take?

- What are the expected costs?

- Flow wrapping vs shrink wrapping

- Flow wrap printing

- Why choose WePack?

Looking for WePack's Flow Wrapping Services?

What is flow wrapping?

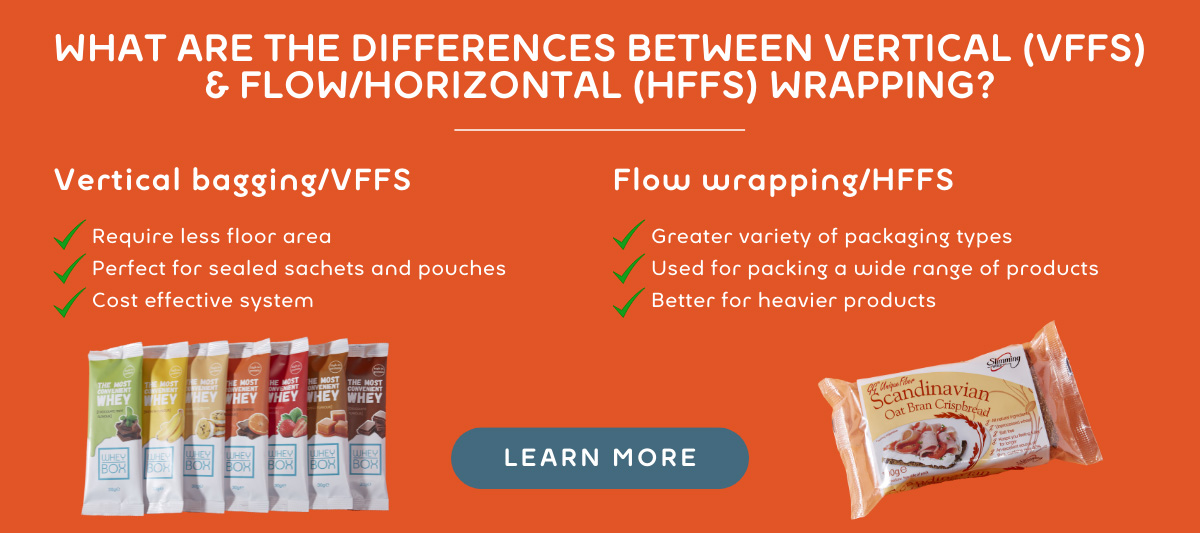

The product moves horizontally along a machine, then wrapped in film and sealed at either end by horizontal flow wrapping machines.

When your product is flow wrapped you end up with a similar bag to what is produced by a Vertical Form Fill Seal service. It will look something like this:

Flow wrapping is also called horizontal bagging, pillow-pouch wrapping, fin-seal wrapping and crimp-seal wrapping.

What type of product is flow wrapping suitable for?

Any solid item that can be pushed along a horizontal belt is suitable for flow wrapping. A chocolate bar, a pack of biscuits, a pack of tissues, a scratch card; any product that needs to be put into a bag that can ultimately be pushed.

Small granular items do not work for flow wrapping – vertical form fill seal is best for this kind of product.

What will the bag look like?

Conventionally a bag produced by flow wrapping is rectangular, though square bags can also be created. The bag can be printed, clear or a single colour.

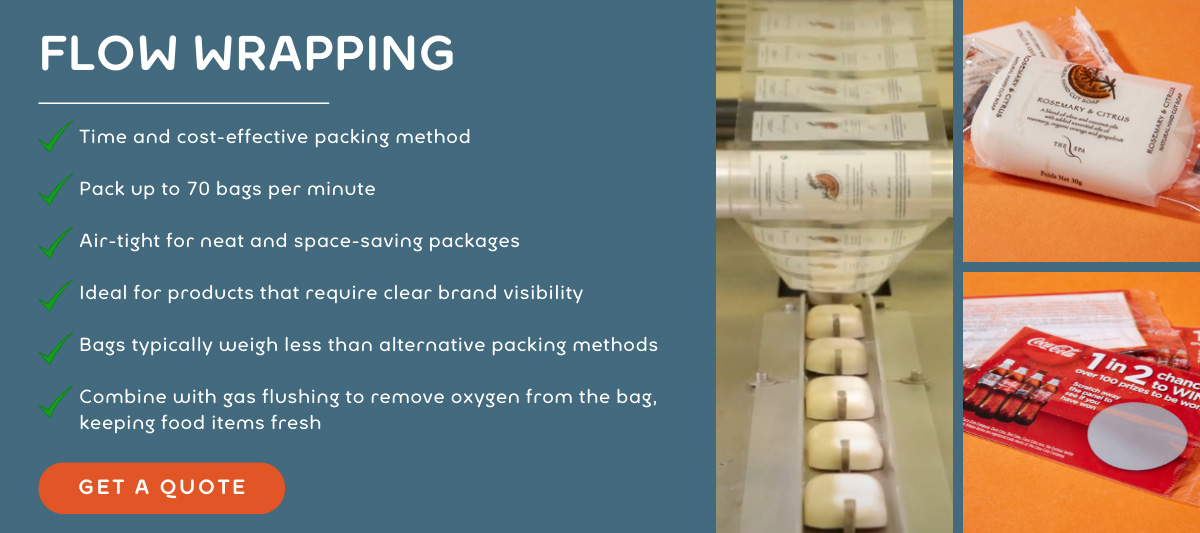

What benefits does flow wrapping offer?

Flow wrapping can preserve your raw material and offer protection.

Good flow wrapping restricts the packaging around the product so that it won’t move a lot in the package and be disturbed. The material used to seal the pack is also kept to a minimum so that the tails aren’t too long.

This means the pack can be neatly placed in outer packaging, reducing the number of resources needed and aiding transport.

Flow wrapping can also be combined with gas flushing. Gas flushing helps preserve your food by injecting a nitrogen mix into the pack. This displaces the oxygen in the bag.

What materials are used?

Just like vertical form fill seal, the packaging materials for a flow wrapper are made of either:

- polyethylene terephthalate (PET) - a common thermoplastic polymer resin of the polyester family, often used for containers of liquids and food.

- polyethylene (PE) - the most common plastic in use today. It has several key usages including plastic packaging.

Both are common types of plastic. They are strong, robust materials that keep products fresh.

How does flow wrapping work?

- The product is manually fed onto a conveyor belt

- The conveyor belt carries the product into the machine where the film is tucked under and over the product to cover it

- It then moves along the conveyor belt to the end sealer where the film is crimped to seal it and cut to separate the products

Watch this video to see flow wrapping in action:

What quantities can you work with?

Generally, we work with 2,500 to 500,000 packs, though can accommodate larger quantities. If you need more, just get in touch and we can discuss options with you.

How long does the process take?

Depending on size we can pack at 65-70 packs per minute.

What are the expected costs?

Prices vary depending on the specification of the work involved. To find out how we can help devise a packing solution for you and what information we’ll require to give you a quote,

Flow wrapping vs shrink wrapping

Flow wrapping and shrink wrapping are two very different wrapping methods.

| Flow wrapping | Shrink wrapping | |

|---|---|---|

| Process |

|

|

| Typical products |

|

|

| Benefits |

|

|

Flow wrap printing

Printing options are available whether you need something simple such as a product tracking number or a fully branded design. Branded options will increase the cost of the overall job.

Why choose WePack?

With over 25 years’ combined experience in contract packing, we pride ourselves on our ability to rise to a challenge and solve problems.

We will find a cost-effective and efficient packing solution that meets your requirements, being used to working with both straight-forward and complicated bespoke jobs.

Need a full service from packing to distribution? We can do that too!

Related content

- Blister packaging and clam packaging what they are and why your business should be using them

- A Guide to Vertical Form Fill Seal (Vertical Bagging)

- Everything you need to know about contract packing, why your business should use one and how to choose

To find out more about flow wrapping and horizontal bagging please contact WePack on 0115 852 9000 or get in touch via the form below.